How to cut a plastic panel at home

In our time, you will not surprise anyone with inexpensive and quick repairs. To do this, many owners buy cheaper and more affordable materials or make repairs themselves. But there are those who prefer to use two methods to improve their homes. And in this case, you cannot do without plastic panels and good knowledge of "How to cut a plastic panel at home?"

Feature material

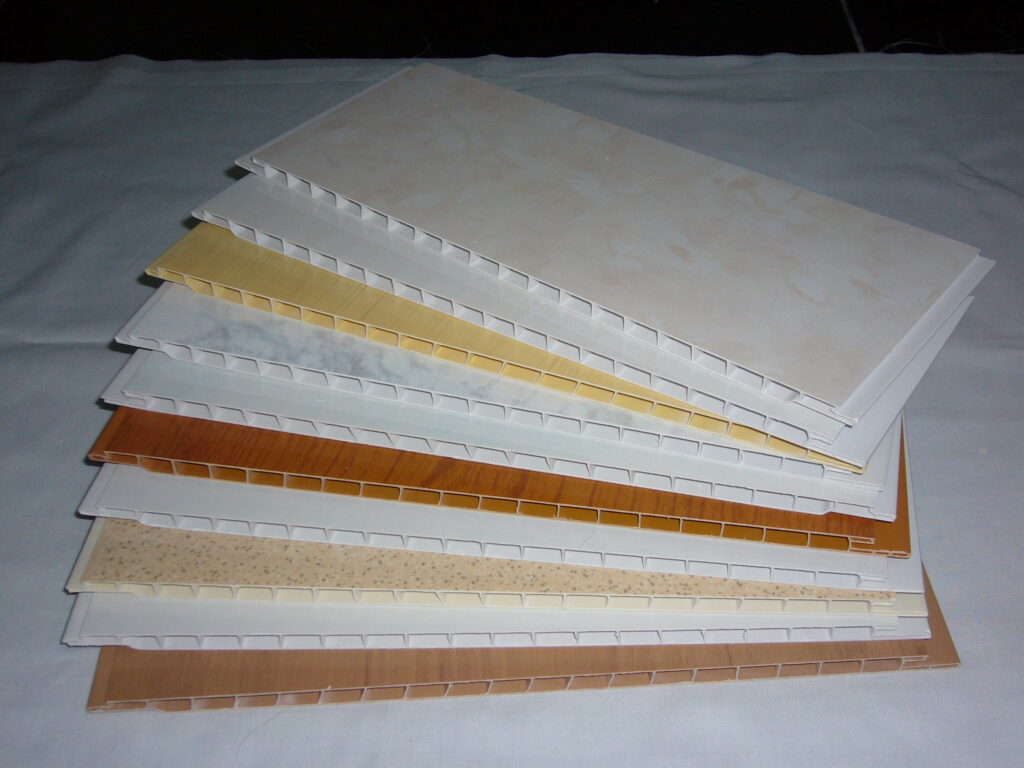

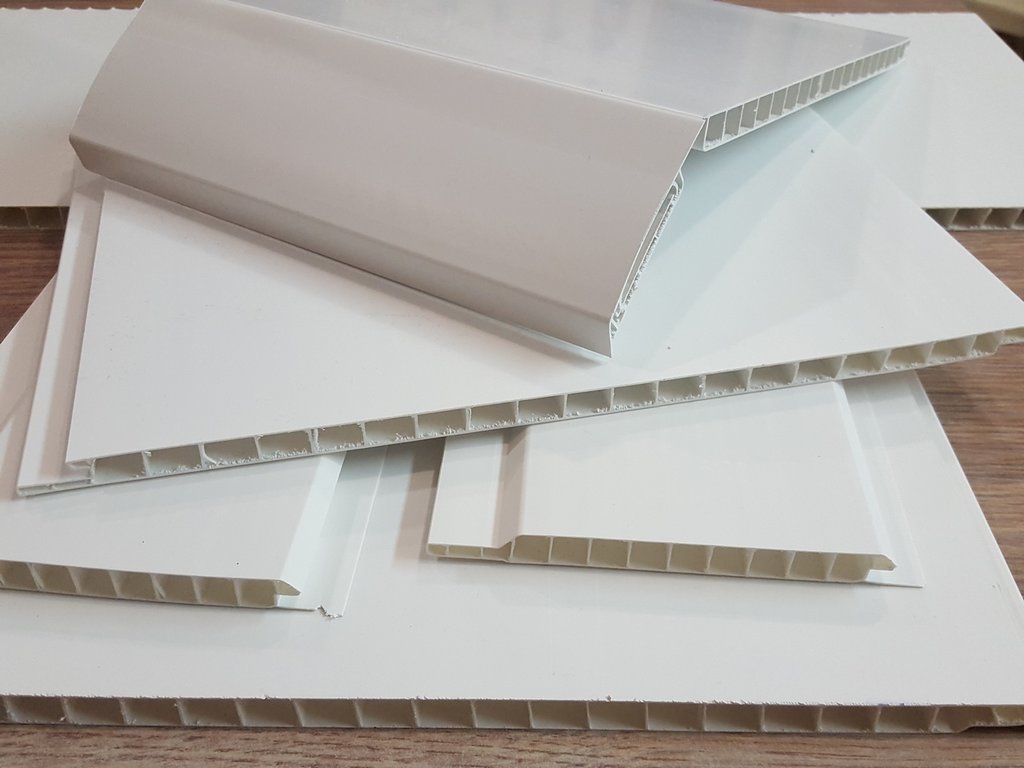

PVC panels are a simple finishing material, in the manufacture of which the extrusion method based on raw materials is used - polyvinyl chloride. Due to its advantages, the material (plastic) has taken a solid place in the market. It is waterproof, easy to clean, inexpensive, and comes in a wide range of colors.

For the manufacture of plastic panels, the molding method is used. To give the desired color in one tone, additional dry mixtures, and for drawing a picture - thermal printing, using an auxiliary roller heated to a high temperature.

Important! If offset printing was used when applying different types of patterns, the cost of PVC panels will be much more expensive.

How to cut PVC panels

When using this material, the main question is - How to cut and saw PVC panels at home? At first glance, everything is simple, since the material is quite durable. But there are many pitfalls with this procedure: the panel may crack, the plastic cannot withstand the load, the cuts will be crooked, resulting in spoiled material and unnecessary waste.

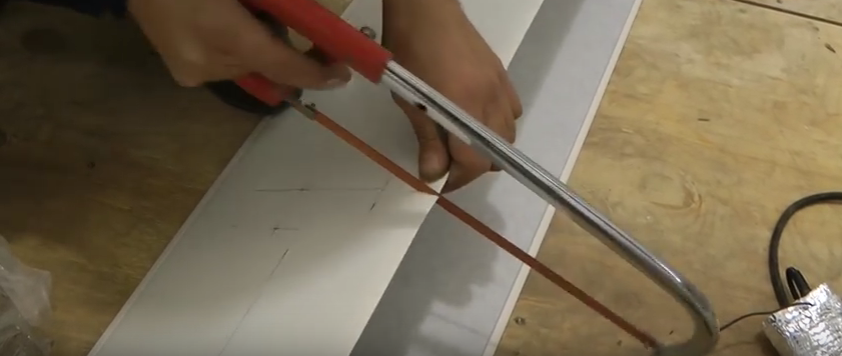

Cutter

A universal cutter is considered not a bad option for cutting PVC panels: not expensive, comfortable in the hands, easy to lift, does not take up much space (due to storage). Produced by many manufacturers, it is always available in specialized stores. If you buy a high-quality cutter, it will be simple and easy to work, the cuts will be without chipping.

Also, for cutting PVC sheets at home, you can use a modern "lifefak" - make a cutter at home. You will need a metal strip (width - 1 cm, thickness - 2 mm), a sharpening stone, electrical tape. On the one hand, the workpiece is cut at an angle of 45 degrees and sharpened, on the other hand, a handle is made of electrical tape for easy holding and safe use.

Note! A multi-purpose cutter is not your choice for cutting plastic panels when curved cuts are needed. The cutter cuts in a purely straight line.

Hacksaw

A hacksaw is a well-known tool, an inhabitant of every house.Thinking about: "How to cut plastic", you can remember about a hacksaw, be it for wood or metal.

When choosing, you need to know a couple of patterns:

- The blade should not be jagged to the side, there is a possibility of cracking when sawing the plastic panel;

- The teeth on the hacksaw should be small (used for transverse dusting), so as not to spoil the panel with an uneven cut.

It is also worth noting that the hacksaw makes it possible to cut plastic panels in several pieces. The main thing is to fold them upside down and in a pile, holding them all at the same time. Regardless of the advantages, there are also disadvantages - the repair will take a long time.

Important! When choosing a tool such as a hacksaw, you do not need to overdo it with physical activity on the plastic panels. Strong force can damage the PVC sheets.

Jigsaw

The jigsaw speeds up the sawing process, whether it's crosscut or longitudinal. It copes well with curly sawing, delicately cuts out the necessary convolutions. In a straight line after sawing, there are no jags or ragged edges.

When working with a jigsaw, it is important to consider some advice from experts:

- Operate at low revs only. Plastic panels will begin to melt at a high temperature of the tool, the cut will not be even, the PVC sheet is damaged, and toxic fumes are naturally dangerous and unpleasant.

- Switch off the pendulum stroke. It will be easier and more comfortable to work.

- Do not overload the panels. The material is practical, but delicate enough. One is not true, a sharp movement - plastic panels are unsuitable for repair.

- Use a jigsaw blade with the smallest teeth. Better cuts.

Additional Information. With an electric jigsaw, you can cut several panels at the same time, while the length of the tool blade should correspond to the height of the folded sheets.

Knife

Coming from the hardware store, thinking about repairs and the question "How to cut a plastic panel?" the first thing that comes to mind is a knife.

Yes, a knife - an improvised home remedy can also help in sawing plastic panels, if there are not many of them and there are no other options.

It is also clear that when using a knife for cutting, the repair process will be delayed. And your work will be hard and most likely thankless (jags, uneven cuts, broken plastic panels as a result).

Which knife to choose:

- A simple table knife (kitchen) is the worst of the options. Cuts can be made by sweating a lot and sharpening the blade as best as possible.

- A special (construction) knife will do the job best, choosing among three options. Blade thickness 18 mm, there is a chance that it will not break, more comfortable to hold in the hand.

- Stationery knife for paper - it is much smaller (blade thickness 7 mm or 10 mm), you will have to work slowly, for a long time and very carefully.

Do not forget that when working with a stationery and construction knife, the master must be very careful, because part of the blade can break off and injure.

Important! When choosing this method of cutting plastic panels at home, use a ruler, angle or level as an aid for making a straight cut. Also, spend several times at the same incision site, then achieve the desired result through a fracture.

Circular

A circular or electric circular saw is a powerful construction tool whose main task is to work with wood and materials similar in spirit.

But it is possible, by installing thinner discs with small teeth, to work with plastic panels and laminated blanks. If you have such a tool at home, then it is more profitable to buy a new disc than a universal cutter or jigsaw.

The disadvantages include the weight of the tool. From all possible options that are used for cutting plastic panels at home, the circular is more overall, and it is more difficult to work with it.

The rules for working with a circular when cutting PVC sheets do not differ from the principles of working with a jigsaw. Use the lowest speed possible and do not put too much stress on the cutting material.

Bulgarian

The most convenient and practical equipment in the hands of a master for cutting plastic panels is considered a grinder.

The benefits include:

- perfect straight cuts;

- high-quality curly patterns and cuts;

- the gaps of the cuts can reach up to millimeters;

- ease of use;

- tool weight.

But there are a number of tips for work, adhering to them, the process will be much easier and better:

- The cutting disc should be metal and thin up to 1.2 mm (preferably 0.8 mm or 1 mm.).

- Work exclusively at low speeds.

- Use a small tool for ease of holding in one hand.

- Do not use your full weight on the panel or exert supernatural force when pressing.

Important! When working with a grinder, it is better to wear glasses and use a vacuum cleaner, since there is a lot of fine dust flying in the process.

How to cut PVC panels correctly

You need to start by preparing the place for cutting, it should be comfortable, ventilated (with the work of some tools, there is a lot of debris and dust). If it is possible to perform cutting in the yard or on the street, it is worth taking advantage of this.

If you already know how you will cut PVC panels at home, you should also prepare a tool. Depending on the choice (find the right blades, sharpen the knife, choose the right disc or blade).

Prepare plastic panels, take measurements, if you plan curly cutting, draw shapes and patterns on the surface of the sheet. You can use a marker or felt-tip pen. No worries, this material can be easily washed off the surface of the panel.

Important! Some tools allow you to cut multiple sheets at once. For convenience, you need to fasten them with construction clamps so that the sheets do not fidget with each other. And it will be more comfortable to work yourself.

It is imperative to saw or cut the plastic panels, you need to put the front side to you. The rule is relevant both for one canvas and for several folded in a pile.

To cut the panels into two parts, which will be used in further work, they are placed on two supports, the gap between which is not more than 10 cm. The side part of the panels is leaned against the wall.To cut an unnecessary fragment on a panel (not very large), put the required part on one wide rack, fix it, lean against the wall and do the work.

A wonderful device if the sheets lie on two

How to avoid mistakes

The main mistake when cutting sheets and working with plastic panels is not knowing that PVC sheets cannot stand low temperatures. You need to work with them at a temperature of plus 5 degrees Celsius, or even more. If the temperature is lower, the viscosity of the panels decreases, which will lead to chips and notches along the cut line - at best. In the worst case, the plastic panel will simply crack or crumble in your hands.

In any case, inaccuracies, errors and punctures are possible. He who does nothing - he does not make mistakes and does not learn from his mistakes. You just need to know the necessary information, follow the rules, take into account the recommendations, calculate everything a couple of steps ahead, and then there will be much fewer mistakes.

Safety regulations

The main rule is the presence of glasses and gloves, since parts of PVC panels and fragments can fly off during operation. The rest of the safety rules directly depend on the choice of the cutting tool.

Advice! If you use an appliance that connects to the network, you need to remember the rules for using power tools.

Everyone has the right to choose. The tool for cutting PVC panels is no exception and it all depends on the goals that you pursue regarding the repair. Do I need to do it faster, how much work, is it possible to buy this or that tool. It all depends on you, the most important thing is that you decided to repair and already know how to cut PVC panels at home.

Video: how and how can you cut a plastic panel at home?