Description and manufacture of molds for soap making

Today, making handmade soap is a common hobby. Thus, you provide yourself with an interesting pastime and get the opportunity to make a non-trivial gift to your family and friends. What are the best soap molds for you?

Why is it worth making soap

There are several good reasons to start home soap making:

- You know exactly what the soap is;

- You only add what you like;

- Know exactly your own needs and limitations (for example, allergies to certain components);

- As a result, you get a unique and truly exclusive cosmetics;

- This is an interesting pastime, both for yourself and for your children;

- The opportunity to always have at hand unusual, beautiful and useful gifts for family and friends.

Even if you have never done this kind of creativity, give it a try! Perhaps this particular activity will become your favorite hobby. Moreover, it is only at first glance, everything is complicated and incomprehensible. In fact, it is accessible and interesting.

The process consists of the following steps:

- The soap base is melted in a steam bath (some people prefer to use a microwave). The main thing is not to overheat and not bring to a boil.

- A care oil is added to the liquid base, at the rate of half a teaspoon for 150-200 grams of soap.

- Dye is added.

- A few drops of fragrance or essential oil are added.

- The mixture is poured into the prepared form and left to solidify.

Varieties of molds for soap

Soap can be not only useful, but also beautiful. The last criterion largely depends on the mold you choose. Molds can be purchased at a store or used materials at hand, and in some cases you can even make them yourself.

Often, novice craftswomen use plastic containers from yogurt, marshmallows or muffins to produce their own soap. Immediately, we note that at the very beginning of the creative path - this is a completely normal tendency. Some people generally prefer to make soap in one large bar, and then cut it into pieces that are more convenient in size.

If you want to please your loved ones with a gift option, then it is better to purchase ready-made forms in a specialized store, especially since their assortment is unusually diverse.

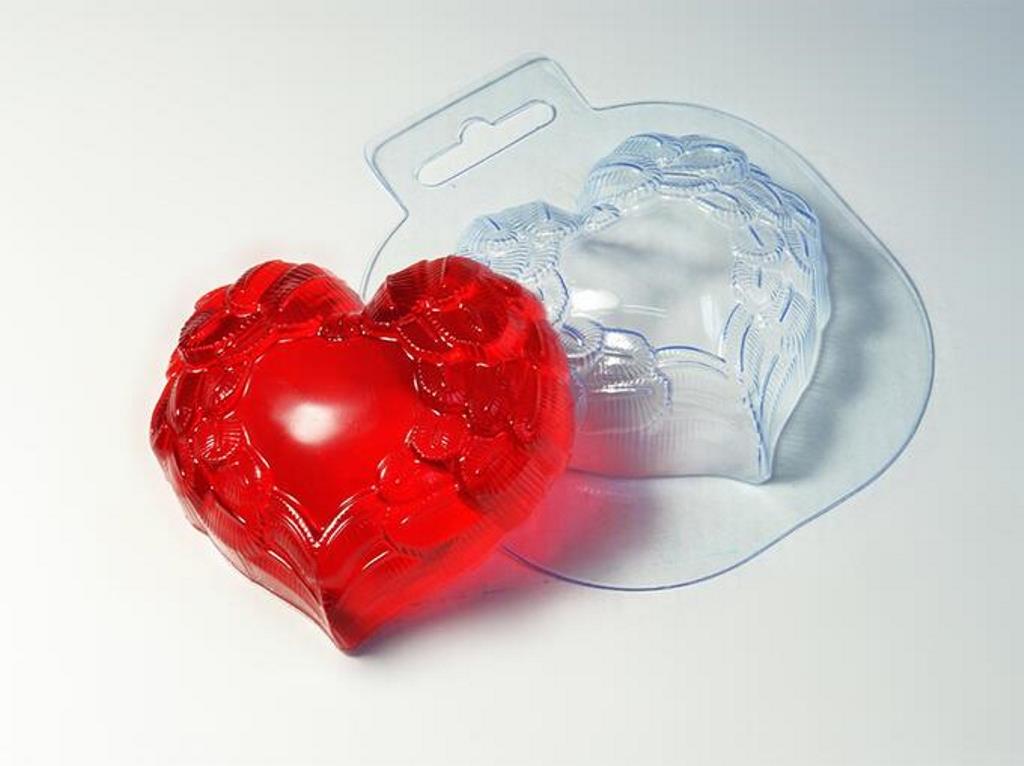

Transparent plastic

These forms are made of high quality plastic. I am very pleased with the variety of shapes and sizes, as well as the affordable price. The disadvantages include only the inconvenient removal of the finished soap from the mold. In addition, transparent plastic molds are very fragile, and if handled carelessly, they can simply crack.

A few simple rules when working with such forms:

- If the soap has solidified at room temperature, then remove it especially carefully.

- First, the plastic edges are gently pushed back, letting in air.

- Then gently "squeeze out" the soap, pressing the middle and down, holding the sides.

- Soap is much easier to remove if placed in the freezer for 15-20 minutes beforehand.

- Allow the soap to dry well before wrapping it in foil.

Silicone forms

Many craftswomen, having tried to work with silicone molds after plastic, do not want to return to the past. Sufficiently weighty forms are made of silicone, with which it is very convenient to work at any stage: both pour the soap composition and get the finished soap.

Silicone bases allow you to create not just everyday items, but real works of art, making the smallest details and components of each figurine authentic. In the process of stretching the edges, the silicone molds do not tear or deform. You can use them for a very long time.

They have only one drawback - cost. For the same amount, you will either get many plastic molds, or one silicone one. That is why they are very attentive to the choice of the latter.

Silicone molds are classified into:

- Two-dimensional (2d);

- Three-dimensional (3d);

- Designer.

Let's dwell on each option in more detail.

Forms 2d are distinguished by a pronounced relief of the frontal part and an even surface below. When working with this form, the soap composition is poured to the full depth of the form. After hardening, the finished soap can be easily removed from the silicone.

For decoration, use glitter, pigment, mother-of-pearl powder. By decorating an already finished product, you can favorably emphasize the relief and make the soap even more attractive. To do this, a small amount of pigment or mother-of-pearl is collected on a dry brush and applied to the protruding parts of the soap figure.

The 3d shapes completely follow the contours of the shape that is being cast. This is the most beautiful soap. Perhaps there is not a single person who would not appreciate the beauty and believability of such products. Only taking out the finished product is a little more difficult than in the previous version. The soap turns out to be voluminous, and the hole in the shape is small. And if the soap has not completely hardened at the time of "withdrawal", then you risk damaging it.

Some manufacturers make additional cuts on such forms, which are fixed in the process of work with an elastic band or a small piece of adhesive tape, and when you need to take out the finished soap, they are freed from them. 3d shapes are the most expensive.

Designer molds for making soap are made of high quality silicone compound. The authors invent such molds themselves or make them to order. It is clear that the circulation of such products is extremely small, and sometimes even the form exists in a single copy. And this guarantees the uniqueness of your gift to your loved ones.

To create an image, designers use different objects: figurines, figurines, plaster or clay products, fruits and much more. It is the design forms that are very convenient to work with, differ in softness and elasticity. Usually, these molds are offered in pink or blue. Silicone is odorless and does not cause allergic reactions during operation.

Advantages of silicone molds:

- The shapes are soft and elastic, but at the same time strong and durable;

- Do not deform, easy to clean and do not require special storage conditions;

- Reliably convey even the smallest details of the figures;

- The finished soap is easily separated from the mold;

- They are odorless, harmless to those who work with them.

By the way, today silicone bakeware is sold in hardware stores today. And they are also suitable for making soap. All kinds of hearts, mice and bears will look great both in culinary performance and in the form of an exclusive soap.

When choosing silicone molds for making soap, pay attention to the following criteria:

- The shape must be sufficiently tight and elastic;

- The walls should not show through, otherwise it is easy to damage such a form during the soap making process;

- Chemical odor and sticking to hands are indicators of poor mold quality;

- Ask about the weight of the finished soap, which will come out of the mold you like. Too small is inconvenient and impractical to use. The optimal weight of a bar of soap is from 80 to 100 grams.

How to make a silicone mold

To make a silicone mold for soap yourself, you need to choose the image of the future figurine, the plastic mold in which you will "create" your masterpiece and, in fact, the compound. Mold material is created from two components: silicone and a catalyst, which, when mixed, harden and form a soft and odorless elastic material. It is imperative to work with gloves. And if the mixture accidentally gets on the table or on the floor, you can remove it with a dry cloth.

- Any figurine or statuette that is in your house, up to children's toys, is suitable as a mock-up of the future soap.

- The fill mold should be taken a little larger than the figure itself. If the container is too large, then the excess amount of compound will be consumed. A plastic cup can be used as a kind of "formwork", especially since they come in different sizes.

- We glue the figurine to the bottom of the plastic container so that it does not float when we fill it with compound. The figure itself and the sides of the container must be sprinkled with vegetable oil, so that later it is easier to separate it from the silicone.

- Preparing the compound. It is important to follow directions and proportions exactly. We take 5 grams of catalyst per 100 grams of mass. Gently mix the mixture, trying not to create unnecessary bubbles. Important: we act quickly, as the mixture begins to thicken before our eyes.

- Fill the mold, tap the walls a little, releasing the formed air bubbles, cover it with a piece of paper so that no debris gets in, and wait at least 10 hours.

- To get rid of the resulting form from the formwork, we cut the container.

- You can remove the base through the hole where the figurine was glued to the bottom. If the relief is complex, then it is better to carefully cut the shape. Don't worry if the shape doesn't work out solid. Before pouring the soap composition, you can connect it with tape and then the cut will not affect the finished product in any way.

- Soap made from self-made molds is unique in its kind. And the form is not difficult to make, you see.

Soap making is a process that will bring a lot of positive emotions not only to the “soap-maker”, but also to those lucky ones who will receive a soap made with love as a gift. A little imagination and a sincere desire to make loved ones a little bit happier will guarantee you success.

VIDEO: DIY silicone molds for soap.