Manufacturing technology and self-melting glass at home

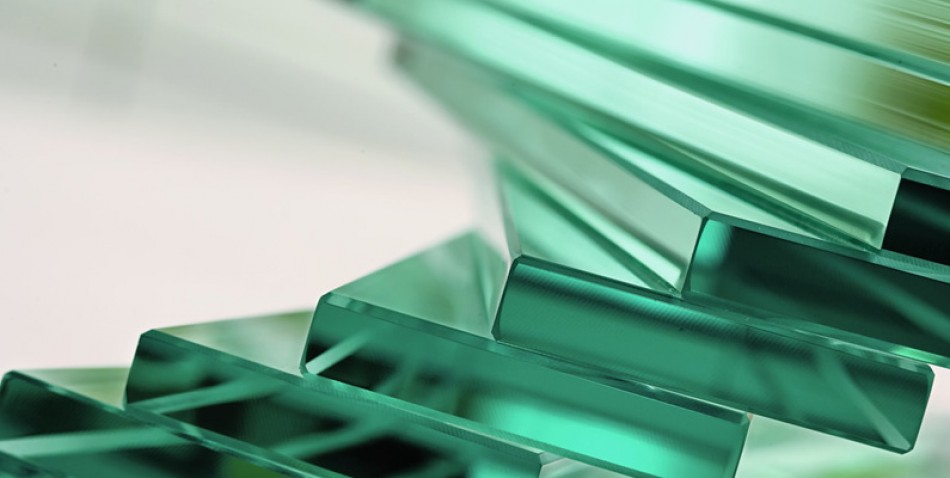

It is impossible to imagine modern life without glass, because it is present in many essential items. Laboratory equipment, clocks, cameras and cameras, incandescent lamps, dishes, interior items - all this and much more are made of glass or with its use.

If you still do not know how glass is made from sand, then we will tell you about how the production process goes on an industrial scale and at home.

How glass is made from sand

Most likely you know that sand is needed to make glass, and indeed, sand is the most important ingredient. To make the glass product transparent, quartz sand without metal impurities is used, which gives the material color shades.

Since quartz sand has a melting point of 2300⁰C, components are needed to help lower it to make the manufacturing process easier and more affordable. This ingredient was sodium carbonate or ordinary soda ash, thanks to which the melting temperature was almost halved.

Because of the soda, the glass is water-permeable, which makes it impractical in everyday life and in production. To give the material strength, calcium oxide or lime is added to the alloy. Additionally, magnesium or aluminum oxides may be present in the composition for maximum resistance to physical and chemical factors.

For the production of thin decorative glass, for example, crystal, lead oxide is used as an additive, which makes the products shine and fragile. Lanthanum oxide is usually present in eyeglass lenses due to its ability to refract light rays.

Sapphire glass for glasses is made with the addition of aluminum oxide, which gives it maximum hardness and resistance to physical damage. To make colored glass, iron oxide is added to the alloy to obtain red, nickel for brown and purple hues, copper and chromium for green, cobalt for blue and other metals.

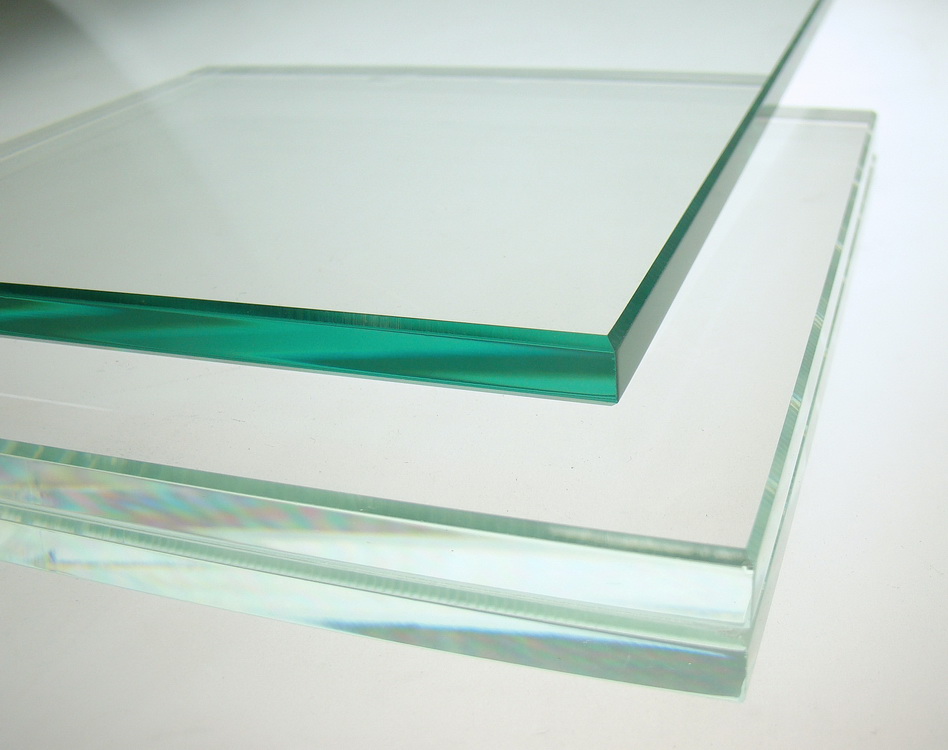

In production, glass is made in several stages: at first, the key components are melted together in a furnace until a homogeneous alloy is obtained, then they are sent to a container of tin, which does not mix with the glass, while maintaining its homogeneity. Already at this stage, the glass gradually cools down, becomes smooth and thin.

The alloy completely cools down when moving along a conveyor, the length of which can reach 100 m, this is necessary to prevent the formation of excessive pressure inside the alloy, which can lead to future rejects.After the conveyor, the glass is further processed to create various products.

How to make glass at home with your own hands

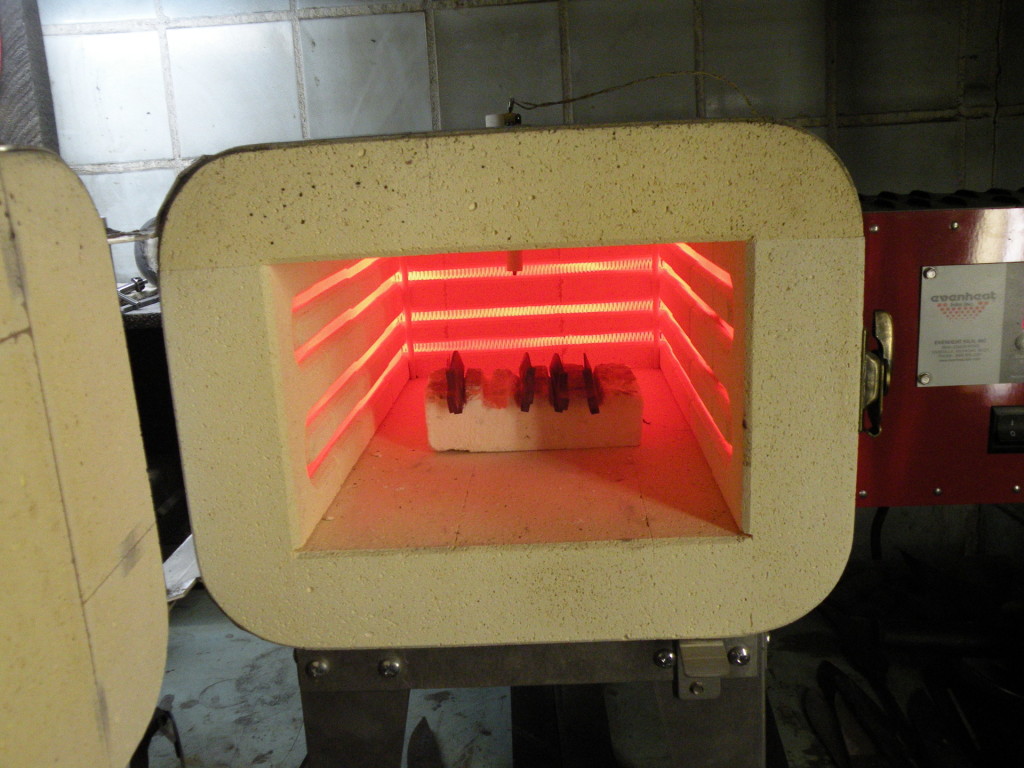

To make glass at home, you need a special oven that will heat up to high temperatures. At home, they use a muffle, electric or pot stove, as well as a charcoal brazier.

The second option is simpler, but unsafe, since during heating to hypermaximal temperatures, the grill can melt itself. We will tell you how to cook glass in a special oven.

- Prepare a refractory crucible (melting pot).

- Pour sand, soda and lime into the crucible, and the impurities should occupy no more than 30% in the composition.

- Place the crucible in the furnace and melt the composition at the highest possible temperature (1500-1700⁰C).

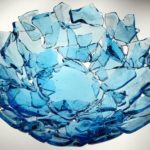

- After the components are melted, pour the liquid alloy into the casting molds.

- The last stage is firing in a furnace cooled to 400-600⁰С. This will make the glass product solid and durable.

This is how you can make glass at home if you have special equipment.

Important! Observe safety precautions when working: use a welding mask, heat-resistant gloves, do not come close to the furnace.

How to melt glass at home

If you want not to weld, but to melt a glass product, then you cannot do without special equipment, because glass does not belong to low-melting materials.

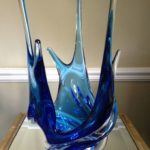

There are two methods of melting: casting and bending. In the first case, special forms are filled with liquid glass alloy, and in the second case, the composition melts to a thick, viscous state, and glass blowers work with it, giving the mass various forms.

Glass melting point

The exact melting point depends on the presence of impurities in the composition. Ordinary transparent glass melts at 700-750⁰С, glassware at 1200-1400⁰С, and quartz glass - 1650⁰С. In industrial production, the temperature is maintained in furnaces at 1600⁰С.

Using a glass melting furnace

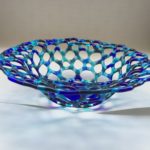

If you are interested in how to melt glass at home, then professional equipment will come in handy, namely, a muffle furnace, whose design ensures heating to the highest possible temperatures. Today there are muffle furnaces capable of heating up to 2000 ° C. Using such designs at home, you can easily make jewelry or other glass products by melting bottles or other glass containers into completely new products.

Use molds, but you need to apply a special compound to them so that the glass comes off easily. Set the mold so that the composition cannot drain beyond its borders. Arrange the items in the oven so that when melting, they flow directly into the molds. Heat the oven gradually to allow the mold to hold. After the end of the casting process, lower the temperature to 500 ° C and leave in the oven for annealing.

Important! Keep a child out of the equipment, as this can be life threatening.

Now you know that you can make and melt glass even at home, if you have the raw materials and special equipment at your disposal.The main thing is to observe safety precautions when working with high temperatures and carefully read the instructions for operating the muffle furnace, so you will protect your health while experimenting with glass at home.