Review of food waste disposers - dispensers

Disposal of food waste is one of the important problems of modern society. Therefore, food grinders are now very popular. Professionals call such a device a disposer.

Sink disposer - what is it

A disposer is a mechanism that is built in under the sink in the kitchen. Thanks to such devices, all small waste products are ground and thereby disposed of. This helps to reduce garbage disposal trips and, most importantly, to get rid of unpleasant odors in the apartment.

Food particles entering the drain pipe cause blockages. This malfunction is not always quickly resolved by cleaning with special chemicals. The disposer will allow you to forget about clogging the drain in the kitchen forever.

The main advantages of the sink food waste disposer are ease of use and long service life. With proper and careful handling, the device can last from 10 to 15 years. High-quality grinding of products contributes to the rapid disposal of waste, cleaning the pipes from the formation of grease deposits.

The disadvantages of an electrical device include:

- significant increase in water consumption;

- high use of electricity;

- rise in the cost of utility bills.

In this regard, the induction option is more economical, which does not need to be connected to the network, but an increase in water consumption is possible.

Another significant drawback of such devices is a very noisy operation, especially when crushing solid waste.

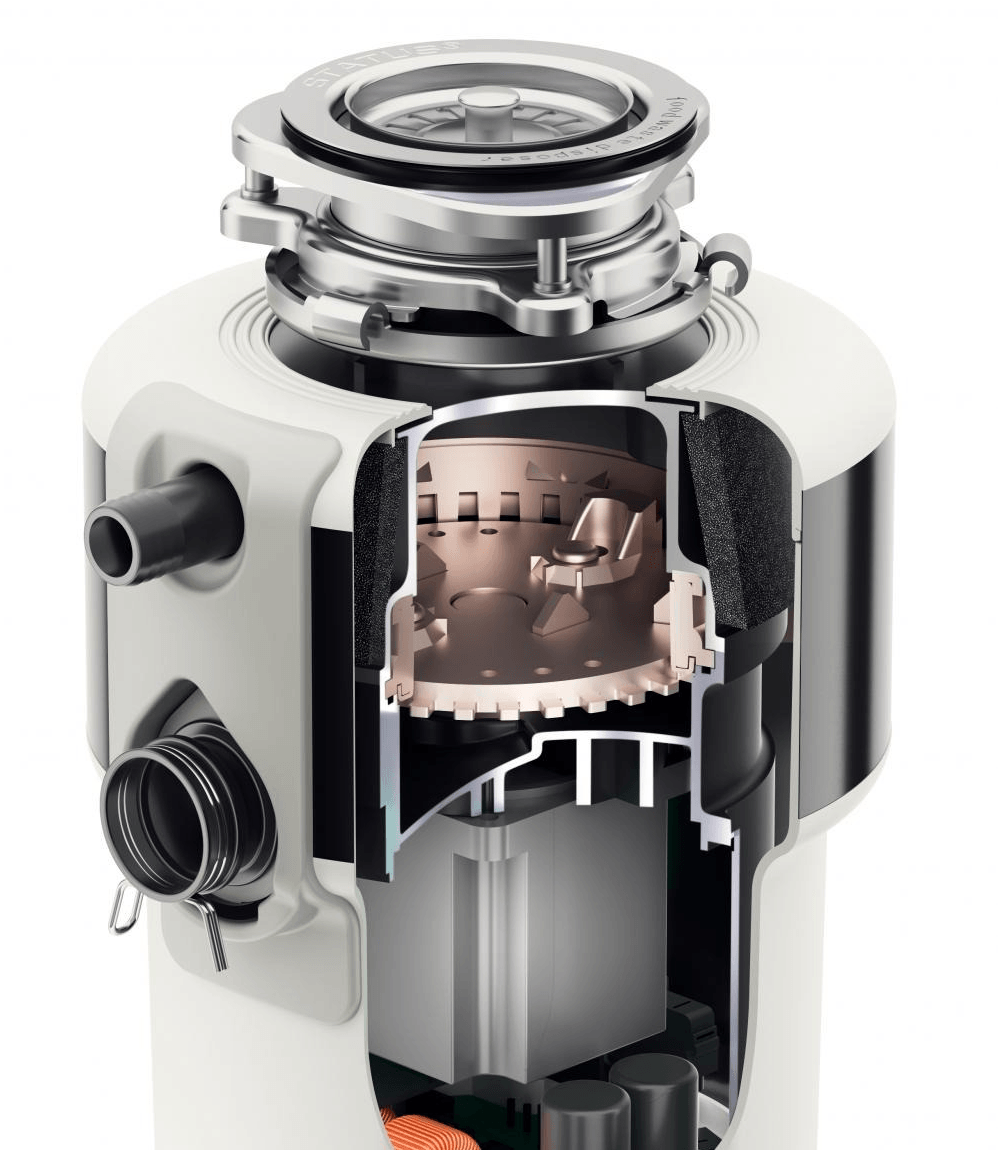

How does a food waste shredder work

This kitchen appliance shreds the waste that gets into the drain and thus simplifies the process of passing the waste through the drain pipe. It is powered by the mains and is installed at the waste outlet under the sink. The chopper has the shape of a tank, in which the engine is built, and also a chamber for chopping food with a special grater is located in it. Under the force of pressure, the waste passes through special nozzles in the form of graters, which turn food into porridge. She, interacting with water, easily moves along the sewer canals.

According to the principle of work, disposers are divided into two main types:

Electric - powered by an electric motor. Products in such a device are evenly distributed by centrifugal force along the walls of the chamber, on which graters are mounted. After crushing, they are sent to the sewer and disposed of. Electric shredders are divided into:

- devices of continuous operation;

- with partial loading of waste.

The use of the system significantly increases energy costs and water consumption.

Induction - autonomously driven. No electrical connection is required, so electricity is saved. However, the average water consumption increases. Special knives are installed in the structure, which are located at the required distance from the drain hole and work from the flow of water. They are completely safe for humans.

How to choose the right one for your kitchen

Someone prefers proven brands, while others are more impressed by economical and functional models. When making a choice, one should proceed from:

- washing parameters;

- functional features;

- reliability of the manufacturer.

When choosing a food waste disposer for the kitchen, you need to pay attention to the following criteria:

- Engine power. Not only the efficiency of the device depends on it, but also the service life.

- The size of the case is of great importance. The larger it is, the more crushed waste will be able to pass through it per unit of time.

- It is important to pay attention to the number of modes. Some include multiple speeds. They contribute to the most efficient crushing of waste with different densities.

- Many manufacturers produce devices with different attachments, which significantly expands the range of processed waste.

The ideal disposer should have the following options:

- built-in automatic overload protection;

- increased noise insulation;

- reverse rotation function;

- antibacterial coating inside the structure.

Additional criteria

Some devices may have additional functions.

If you need to get rid of odors from the sink drain hole, as well as to avoid the growth of bacteria, you should choose models with a special antibacterial coating, which is located in the inside of the case.

The power button can be built into the worktop next to the sink. Also, the switch can be a chopper cover, the rotation of which turns on the device.

Manufacturers have added additional functions to modern models: a pneumatic switch and overload protection.

Rotation speed of discs

Directly depends on the engine power. Consuming a large and uninterrupted stream of waste will require a very powerful motor that will set the maximum rotational speed of the discs.

It is very important when processing solid products. However, in order to avoid damage to such systems, you should avoid getting into them metal, glass, plastic and other small, but rather strong objects. Most modern devices are equipped with an automatic shutdown system, but still it is not worth the risk.

Power

It is selected depending on the purpose of the equipment. High power will be relevant for the use of the shredder in large bars or restaurants. For home consumption, an application with a lower power rating is quite sufficient, which will save utility bills.

The more powerful the unit, the more noise it emits, which is not very good for the nervous system of the household. By sound, they resemble the operation of an electric meat grinder, which is constantly on. Therefore, for the home, it is not recommended to use food waste disposers with continuous operation in sinks.

Cylinder capacity

This aspect also depends on the scale of consumption of the disposer. The more and more often the device is used, the more the size of the crushing chamber is needed. The more power, the larger the cylinder will be. The size of the grinding mechanism depends on its size. These are interrelated things by which you can easily determine the purpose of the unit.

To prevent the crushing cam mechanism and chamber from rusting and corroding, as well as failing quickly, they are made of durable stainless steel.

For catering, it is better to use powerful electric models with continuous operation. For the home, the mechanical option is also quite suitable, which implies portioned loading of products. However, it does not require electricity consumption. Such models are inappropriate with a large waste stream, since it is not very convenient to measure out a certain amount of products and only then start the mechanism.

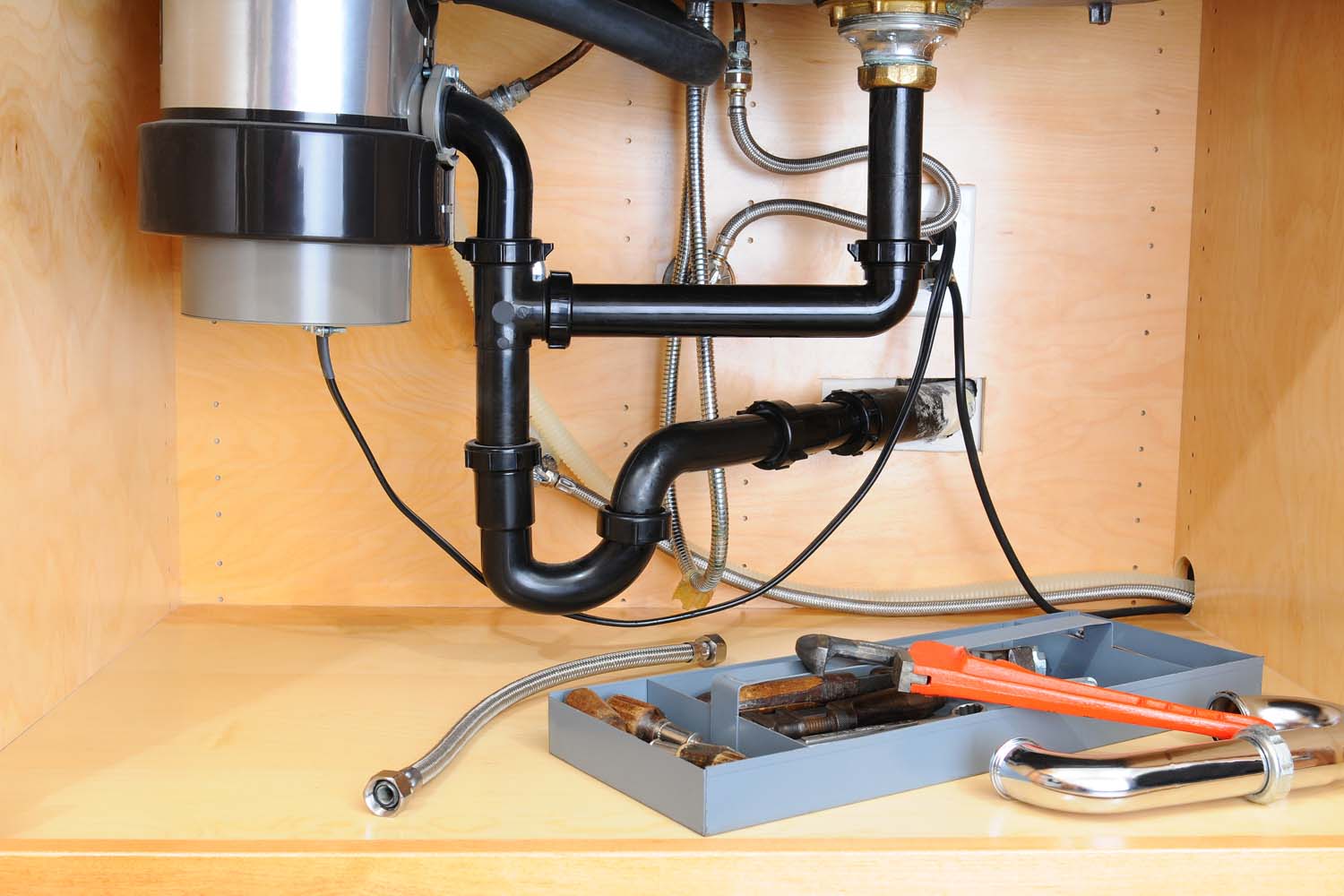

How to connect a chopper

You can connect and install a food waste disposer under the sink either with the help of specialists or independently. This will require minimal engineering skills and tools to operate.

When installing, there are some important points to consider:

- The device is mounted under the sink, and this is an area of high humidity. This means that you should choose an outlet with grounding and protection against moisture.

- Most of the models are designed for sinks with a 90 cm drain. It is necessary to enlarge the hole or replace the sink.

- It is better to give preference to sewer pipes with smooth walls, rather than corrugated ones. Waste remains between the folds of the corrugation and causes unpleasant odors, as well as contributes to the growth of bacteria.

- The device must be installed in accordance with the attached instructions. If there is absolutely no experience in such a matter, then it is better to seek help from specialists.

- When self-assembly, it is very important to follow a certain sequence:

- disconnect the drain pipe from the sink and thoroughly clean all the elements of the drain system;

- a rubber gasket is included with the disposer, which should be fixed under the sink flange;

- then the mounting bracket is installed, which is attached to the shredder. It is attached directly to the device itself;

- using special adapters, one end of the drain pipe is connected to the device, and the other to the sewer;

- the disposer remains to be plugged into the power supply - and it is ready to work.

Rating of the best waste disposers for the kitchen

A huge number of firms that have established themselves in the home appliance market offer users various models of grinders. Each of them has both advantages and disadvantages. To choose the best option, you need to compare the most popular models in the line of the best manufacturers. For this, a small overview is made in the article.

Midea MD1 C-38

Motor power - 380 W. Rotation speed with loading - 2600 (rpm), without loading - 42000 (rpm). Overload protection, manual restart. There is an anti-jam device, long-term operation under load, a three-stage grinding system. Differs in ease of installation, low noise level and protection against sewer blockages. Voltage 220-240 V, 50 Hz.

Bone Crusher BC 610

Despite its relatively small dimensions, the device is equipped with many options. It is just perfect for the budget conscious consumer, and it handles all waste with ease. Thanks to the special structure of the chamber, after the end of the work, food residues are completely removed. The engine rotation speed is 4000 at the moment of starting, and with a load - 2600 (rpm).

The crushing mechanisms are made of durable stainless steel. New generation technologies provide even more comfortable work. High revs and smooth running are achieved by laser balancing of all moving parts of the disposer and engine. This reduces noise and vibration during operation, making it more comfortable to use.

The technology of attaching the device to the sink with three screws and locks, there is a pneumatic shutdown button.

Status Premium 300

Manufacturer - Italy. The most functional, quiet model, at the same time the most powerful. Suitable for all types of sinks. Provides more thorough waste processing and disposal time. Reduces processing costs.

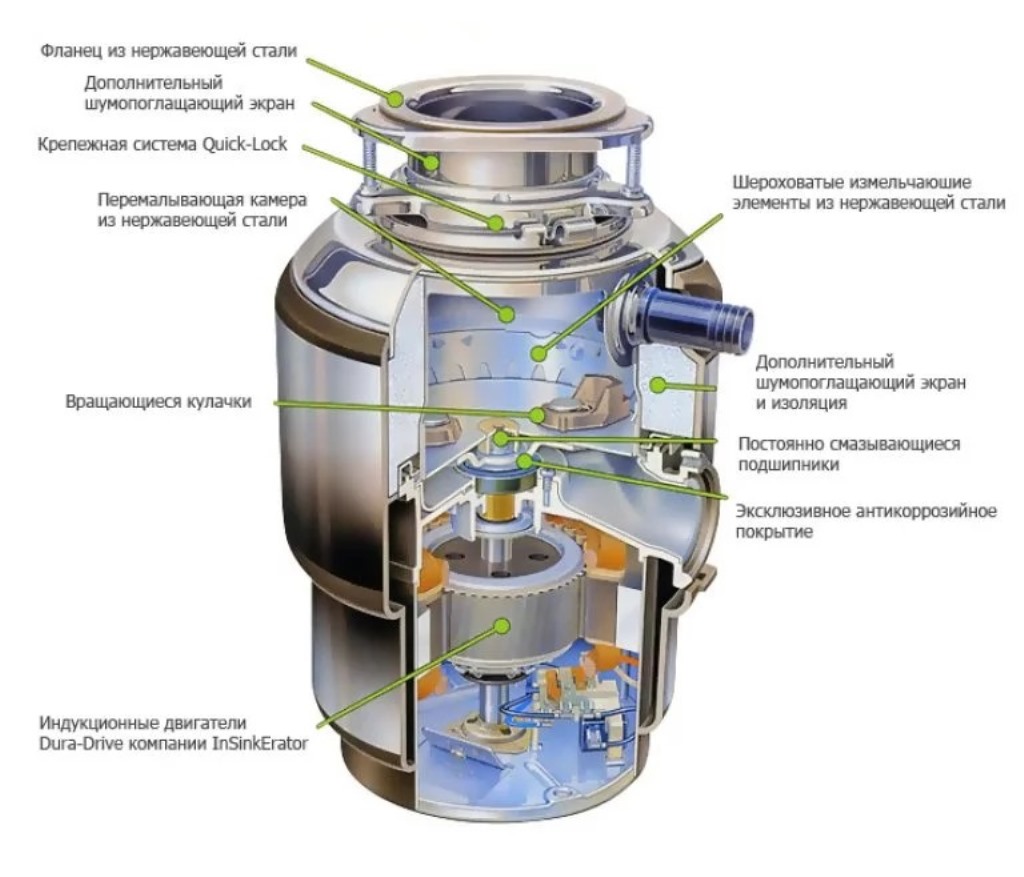

The body, disc, hammers, all grinding elements, fastening lock and polishing flange are made of stainless steel. Equipped with 3-level grinding system and booster traction, high torque induction motor.

The download type is continuous. Automatic overload protection, bolted disc, soft start, automatic reversing mechanism. Built-in pneumatic control system, the button can be built into the countertop near the sink.

In Sinkerator M46

Manufacturer - USA. The loading method is continuous. Induction motor. Shredding jaws with 360 degree articulation. All grinding elements are made of stainless steel.

Designed for a small family. Has an advanced noise reduction system. Overload protection system of automatic type. Loading is continuous.

The grinding chamber has a corrosion-resistant coating, all grinding mechanisms are made of stainless steel. Dimensions: height - 318 mm, diameter - 173 mm, weight - 7160 g. There is a dishwasher connection.

The model is equipped with an automatic reverse, which will release from blockages in the pipes. The mechanism finely grinds the waste, which is removed with the flow of water into the sewer. The device is turned on by pressing the button, and when released, it turns off. The built-in overload protection protects the motor and it will not burn out even if the permissible load is exceeded, but simply shuts down.

Thor T22

Country of origin - China. Electric model with a pneumatic button, without a set of drain fittings. The crushing chamber mechanisms are made of stainless steel. Loading type continuous, overload protection, pneumatic switch.

Maximum engine speed - 1430 (rpm), height - 327 mm, diameter - 182 mm, volume - 1.2 liters, power - 372 W.

Bone Crusher BC810

Manufacturer - USA, country of origin - China. Designed for a family of 4 people. Differs in universal performance in terms of technical capabilities and excellent sound insulation characteristics.

Speed - 4000 rpm, with load - 2600 rpm. The material of the working chamber is a high-strength composite, processed using a special technology and preventing the appearance of pathogenic microbes. Due to the unique structure of the chamber, waste is completely disposed of into the sewer. The service life of the device is over 25 years.

Crushing mechanisms made of stainless steel.Magnetic motor, automatic reloading system, processing method - in-line. Pneumatic switch, complete soundproofing.

This is an innovative model controlled by a remote control. Very easy to operate and safe, even children can use it. Saves time and money.

When choosing a device, you should pay attention to the package bundle. It must necessarily include:

- rubber gaskets;

- fasteners;

- a set of special keys;

- air tubing with a pneumatic button and an outlet branch (if provided in this model).

Regardless of the rating and popularity of the manufacturer, the food waste disposer can last longer if it is cleaned with special cleaning agents several times a year. It is better to use gels rather than powders with abrasive particles. In addition to household chemicals, you can also use simple household cleaning products: soda, lemon or ice cubes.

VIDEO: BoneCrusher BC 610 Dispenser Review.