How the washing machine works

A washing machine is an integral part of the household appliances of every modern person. And in order for such a complex mechanism to last as long as possible, it is worth adhering to many nuances when using it. We will talk further about how the washing machine works, what can be done and what is not worth doing in order to maximize its service life.

What are the washing machines

It is customary to do the washing technique in 2 large groups:

- Mechanical.

- Automatic.

Progress has long been advanced in improving the functionality of the washing machine, so it is inappropriate to devote time to considering a mechanical family. Such models can only be found in technical museums.

The device of an automatic washing machine seems to be much more urgent. It includes a fairly large number of precise electronics, knowing the principle of operation of which, you can extend the period of uninterrupted operation of such equipment for a long time.

Washing machine device - automatic

As mentioned earlier, the washing machine circuit includes many autonomous control elements, which are combined into a single system by an electronic unit.

general characteristics

In an abstract form, a washing machine is:

- Frame.

- Water filling system.

- Washing system for clothes.

- Water drainage system.

There are currently front-loading or top-loading models available. By the principle of work, they are the same.

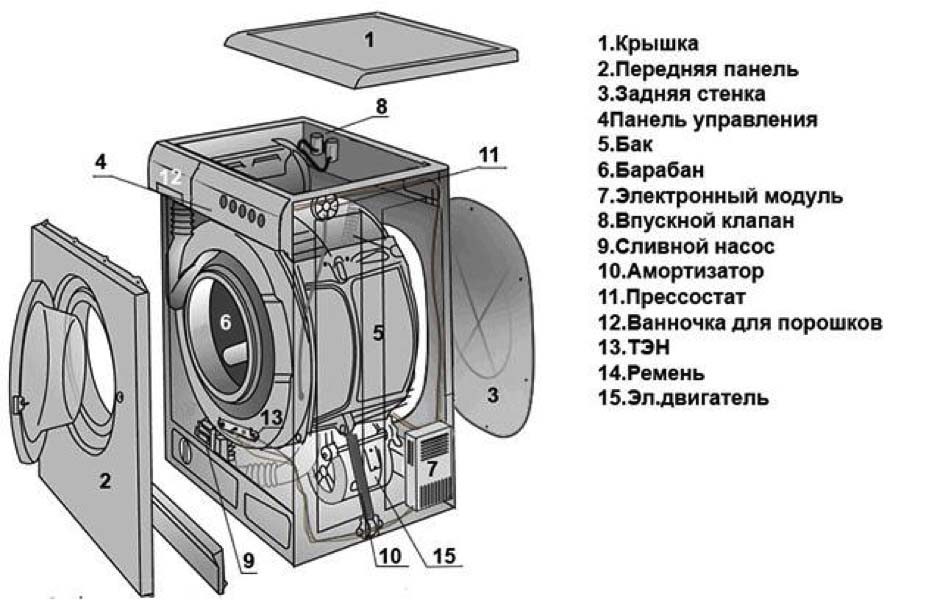

Internal organization

In a robust metal body of the machine, all electrical and mechanical systems are connected together, thanks to which the equipment receives its complete functional purpose.

The body includes the following parts:

- Filling valve.

- Tank and drum.

- A heating element.

- Engine.

- Water drainage system.

- Control block.

All these systems will be discussed later, because the functioning of the washing machine depends to a greater extent on their correct use.

Technical device

Knowing and skillfully using each unit of the washing machine, you can easily extend its service life for a very long time. Let's take a closer look at each technical block of this complex system.

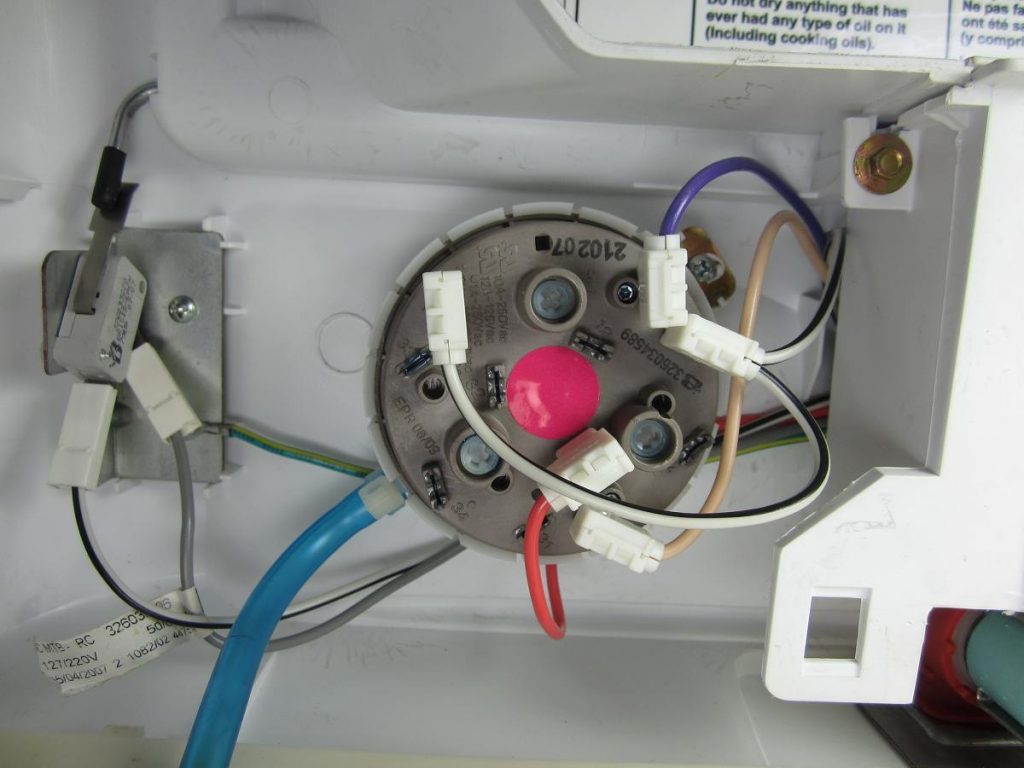

Pressostat

The correct functioning of this sensor directly affects the quality of the washing of things. After all, the pressure switch is responsible for monitoring the level of the incoming water. Accordingly, the more accurate its readings, the better the concentration of detergents in the water is observed.

Note! Improper functioning of the pressure switch can result in overflow of water outside the washing machine tank.

Symptoms of a faulty pressure switch are:

- Start washing without water.

- Incorrect washing level - too much water or too little.

- Frequent repetition of the cycles of pumping out dirty water and supplying clean water.

- Malfunction of any of the washing programs in use.

If any of the above problems appear, you must immediately call the wizard to eliminate it, as well as prevent further failure of other systems.

Water intake valve

This unit is designed as a solenoid valve controlled by the main unit. This valve can have only 2 operating positions - open or closed. Its operation is possible only with a functioning pressure switch, otherwise the control unit will not be able to correctly track the level of water collected in the machine.

Water is supplied through the valve, then the liquid is directed to the container for detergents, after which it enters the tank. Before the intake, water is passed through a grate with small holes - for mechanical cleaning of water from debris.

The main factor in valve failure is the inability to go open. Accordingly, washing becomes impossible. One of the signs of a faulty water supply system is the absence of characteristic clicks when starting a wash program.

Note! In the event of a malfunction, it is recommended to change the supply valve entirely, self-parsing can turn into a deluge, since such devices are supplied in a one-piece plastic case, which is practically not subject to reassembly.

Tachogenerator

A tachogenerator is a device designed to control the number of engine revolutions. Not only the noise of washing depends on compliance with the established operating mode, but also the stability of the washing machine during operation, as well as the durability of the belt transmitting the torque from the electric motor to the drum.

The sensor is installed on the engine, and as its speed changes, the magnetic field indicators of the device are corrected. The control unit, receiving data on such a change, also corrects the number of engine revolutions.

Symptoms indicating a malfunction of the tachogenerator include incorrect drum rotation speed in all washing modes. When soaking the laundry, this threatens with an insufficient degree of cleaning of dirt from the surface of the fabrics, during the spinning, the incorrect operation of the tachogenerator can result in a low quality of this operation, and in the most critical cases - the destruction of the drum rotation mechanism.

temperature sensor

The temperature sensor is another important link in ensuring a high quality wash. This element controls the level of water heating, which means it is responsible for observing the washing regimes.

Having received the readings from the temperature sensor, the control unit regulates the supply of electricity to the heating element, due to which the best temperature match to the selected washing mode is achieved.

A sensor malfunction is determined by the inconsistency of the water heating temperature with the selected program. Measured, as a rule, the degree of heating of glass in a front-facing machine for washing. In models with top loading, it is sometimes possible to determine the health of the sensor only by the presence or absence of errors in the control unit. Most often, problems in the operation of this sensor are determined precisely by the incorrect water temperature, and not by the lack of heating in principle.

Note! The lack of water heating during washing can also indicate a problem in the operation of the heating element.

Other elements

Some modern models may include elements such as an electronic clock showing the time remaining until the end of the wash program. Many cars are equipped with an alarm system about the end of the program.

All these components are brought together by an electronic control unit.

Executing details

As the name implies, this group of parts works by receiving signals from other sensors and does not generate any pulses on its own, and in some cases is even a purely mechanical component.

The list of performing parts includes:

- Electrical engine.

- TEN-heater.

- Sunroof locking device.

- Drain pump.

- Drum tank.

- Damping system (springs, counterweights).

- Drum pulley.

Let's consider every detail in more detail.

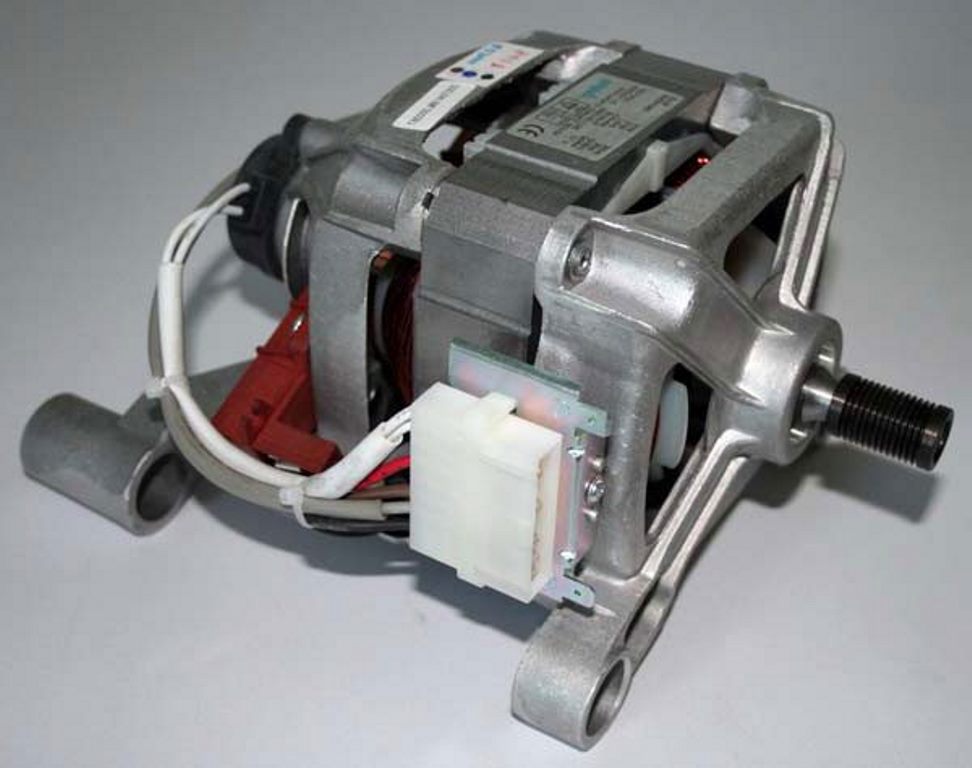

Electric motor

The washing machine motor generates revolutions at all stages of washing for the drum. The torque from it is transmitted to the drum through a drive belt, or a direct connection.

The engine speed is regulated with the participation of a tachogenerator; the control unit is responsible for supplying a particular voltage level to the motor. Thus, the correspondence of the drum revolutions to the selected washing mode is achieved.

As a rule, the electric motor is a fairly reliable component of the washing machine; it rarely fails. The reasons for the breakdown, which are most often observed, are the ingress of water, insects, and foreign objects into the electrical assemblies. This leads to a short circuit in the winding, with such a breakdown, the motor must be repaired, and if it is impossible to carry out such work, it must be changed.

The engine is located under the drum, the most common is the belt connection with the drum.

Electric heater (TEN)

The heating element in modern washing machines is often a consumable part. All because of the low quality and high aggressiveness of water in modern pipelines. Limescale is the main cause of heater failure. Therefore, many manufacturers recommend periodic maintenance of their machines with special cleaning agents.

TEN is a tubular device, the metal cavities of which are filled with a special compound to improve heat transfer.

Located at the bottom of the drum, access to it is quite simple and, if necessary, anyone can replace the heating element.

Note! When carrying out such work, it is necessary to disconnect the washing machine from the mains and drain the water from the tank.

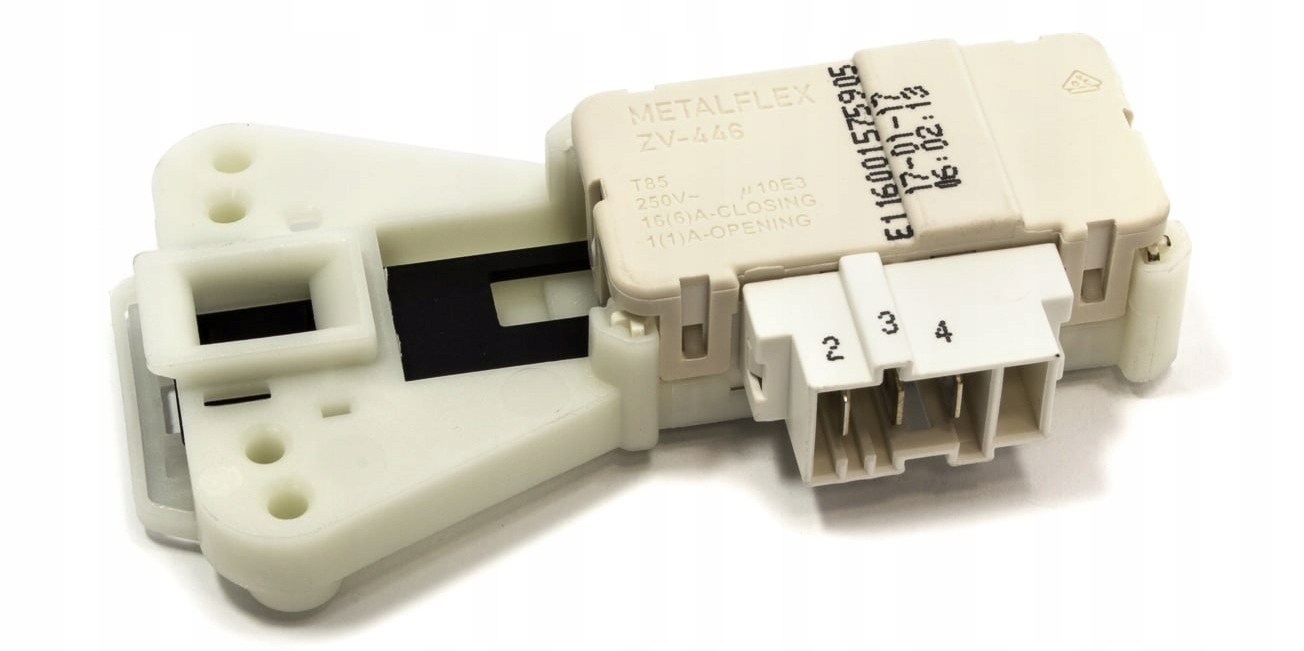

Sunroof locking device

In fact, this system is a simple solenoid lock, which is in the "open" mode when inoperative.

When you turn on any washing program, the hatch for loading things is blocked to exclude the possibility of opening it during the operation of the machine.

After the completion of the selected program, the lock returns to its inoperative mode, opening access to things.

Drain pump

This mechanism is in second place after the heating element in terms of failure rate. Especially if before washing it is not practiced to check the pockets of things and remove unnecessary trifles from them. Once in the drain system, such unwanted parts block the unobstructed drainage of water, which can lead to pump failure.

Almost every machine is equipped with a drain pipe cleaning system, which allows, first of all, to remove unwanted elements from them. After going through several cycles of scrolling the drum with dirty things, the water is usually replaced. For this, the drain pump serves.

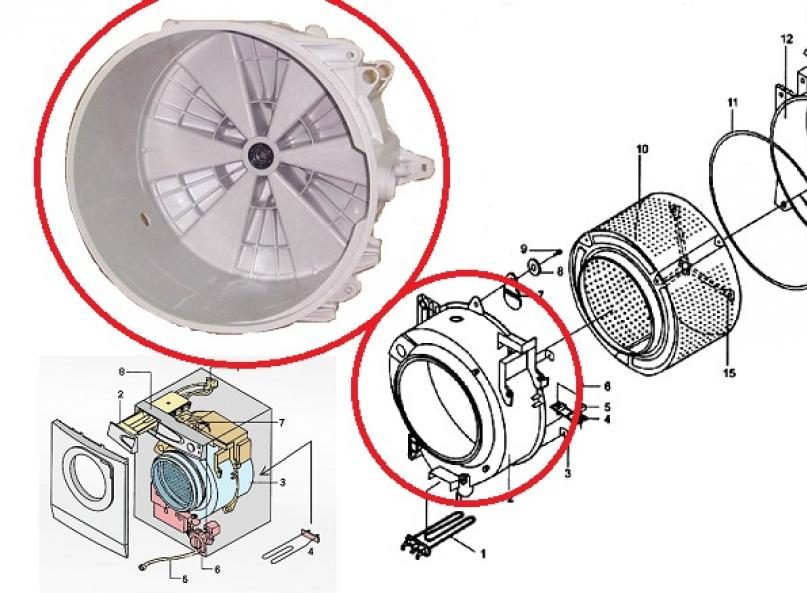

Tank design

The tank is the most bulky element of the washing machine. It consists of a plastic case, which houses a metal drum, a heating element and a thermostat.

On the tank, there are necessarily nozzles for connecting the water supply system and its drain.

Recently, many manufacturers have been using non-separable tanks, in which, if the rotation bearing fails, a complete replacement of this element is necessary, or the purchase of new equipment.

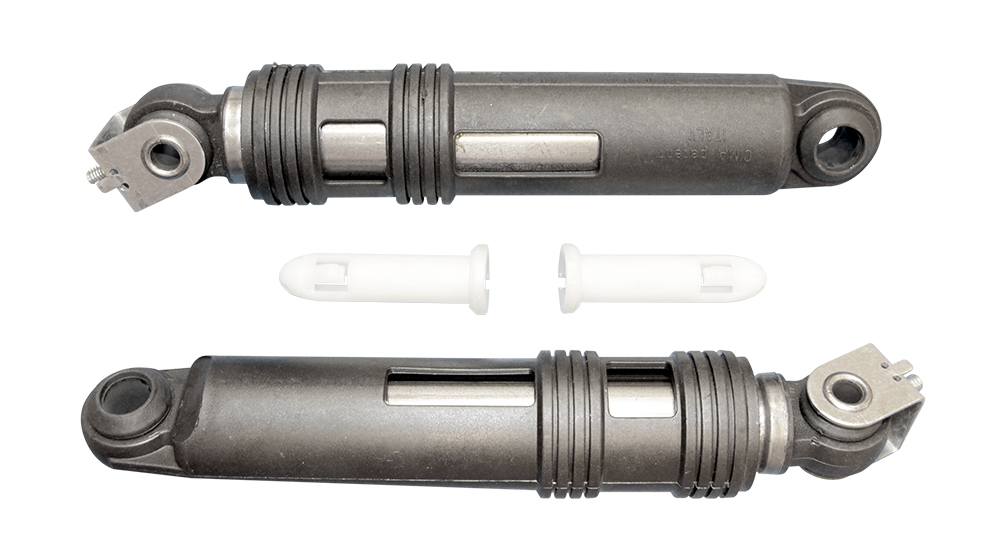

Shock absorbers

When operating at high speeds, the washing machine tank is inevitably exposed to large forces that swing it. Shock absorbers are designed to smooth out such vibrations.

During the operation of the washing machine, they take on all the loads, therefore, they also break down with frequent overloads. The main signs of faulty shock absorbers can be called too strong vibrations of the body of the washing machine. This can eventually lead to a breakage of the main drum bearing.

One of the symptoms of faulty dampers is the periodic flaking of the motor drive belt.

Note! Replacing defective shock absorbers on your own is not recommended, since it requires dismantling the drum mechanism.

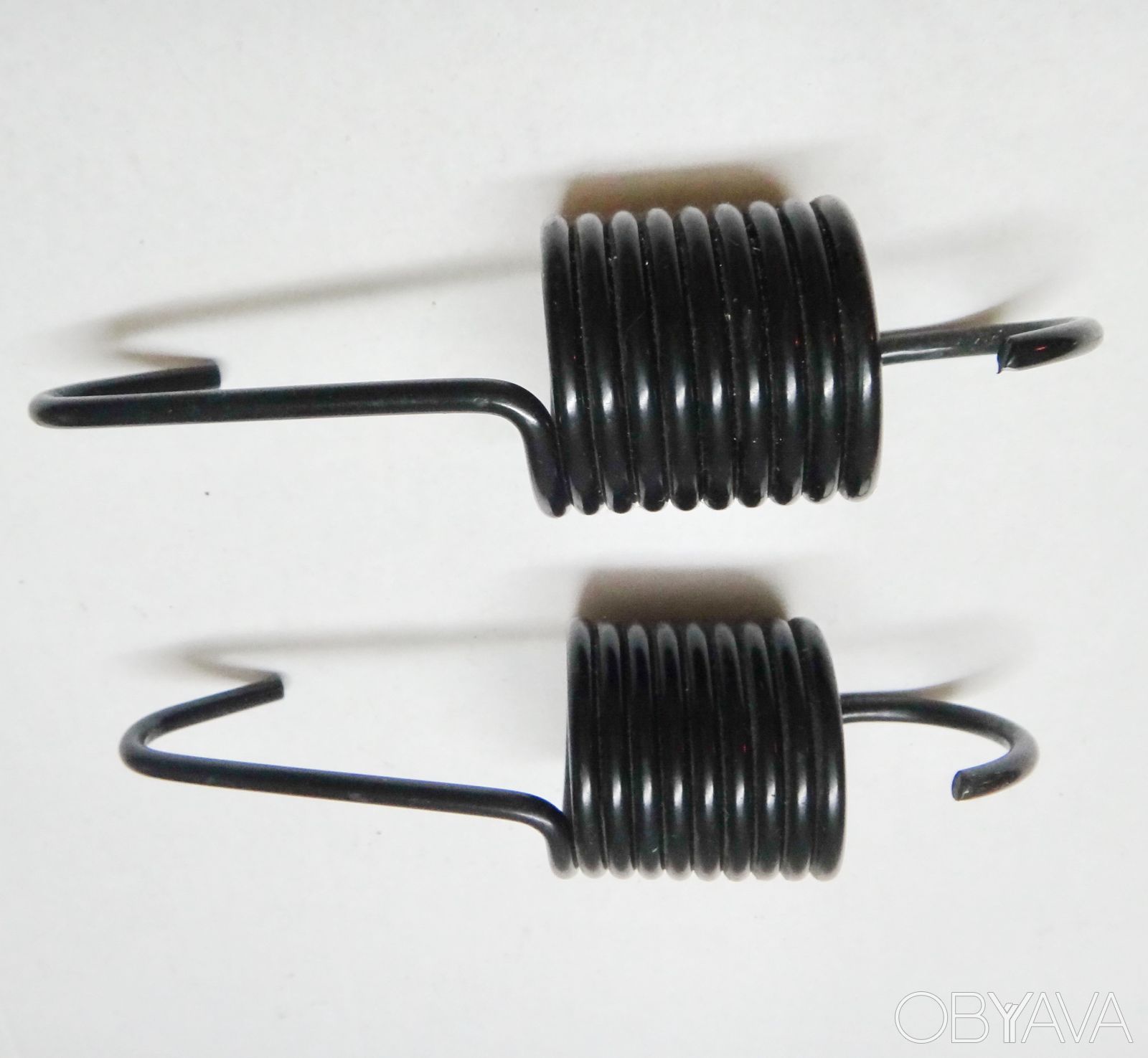

Springs

The springs provide an additional damping effect when the washing machine is running at high speeds. Unlike shock absorbers, which dampen longitudinal vibrations, springs are responsible for the absence of horizontal ones.

It is thanks to them that the tank remains in a relatively stationary state of its axis, as far as possible. Being a simple mechanical element, springs can stretch from frequent overloads, in which case they should be replaced. This can be done without removing the drum. It is enough to open the top cover of the case and carry out the necessary work.

Pulley

The drum pulley is involved in the transmission of torque from the electric motor. Most often, such work is performed by a drive belt; in some cases, you can find models with a direct connection of a pulley and a drum.

This part is quite reliable and can only fail if the belt is skewed, but this practically does not happen under normal operating conditions of the washing machine.

Counterweights

The hardest and most monumental part of the whole "washing machine". It can be made in two types - top plate and side panels. In both cases, it is a dense and heavy element that provides additional vibration damping and prevents the drum from transmitting strong vibration to the body.

To ensure the best stability, ensure that the machine is in a level position when you install it in a permanent place.

Drum

The device of the drum of the indesite washing machine is a metal cylinder with a large number of holes through which water enters and drains to things. The tank and the drum are held together by a rubber cuff.This design allows you to damp vibrations arising from the rotation of the drum, and also ensures the tightness of the tank.

A shaft is attached to the rear of the drum, through which it rotates by a belt drive. A bearing is installed between the shaft and the tank housing, which performs 2 functions at once:

- Ensuring drum rotation.

- Additional tank sealing.

If this bearing fails, a complete tank replacement may be required. This happens in cases where the system is non-separable.

Important! The main reason for drum bearing failure is periodic overload during washing. Therefore, you must always adhere to the requirements of each model for the maximum weight of the laundry available for loading.

Other details

The most important components of the washing machine were considered above, but it also contains other equally necessary elements. More about them.

Dispensing tray

This tray dispenses detergent and air freshener as needed. Depending on the media used, 1, 2, or all 3 sections of the tray can be used. Located on the front panel in the upper tier near the control buttons and information panel.

Rubber cuff

Responsible for the tightness of the connection between the drum and the tank. It can be damaged by sharp objects, therefore, it requires a careful attitude towards itself. For example, using bags for washing clothes.

Hoses and pipes

An integral part of the washing machine is also a series of pipes and hoses. These include:

- The hose for supplying clean water from the water supply.

- Dirty water drainage hose to the sewerage system.

- Connection pipe for drum and dirty water pump.

All these elements are also involved in the washing process. The only problem with using them is the blockage, which is quite easy to remove with a simple cleaning.

Washing process

Having learned from all the previous material how the washing machine works, you can easily start the process itself. The algorithm consists of the following stages:

- Pre-sorting things. In order not to spoil the appearance of their clothes, things are divided into black, white and colored. All three groups are erased separately from each other.

- Checking pockets for foreign items, packing clothes with large locks in laundry bags.

- Load the washing machine drum according to the maximum recommended dry weight for each model.

- Closing the tank of the machine with the front door. It is necessary to make sure that the lock is securely closed, otherwise the blocking electromagnet will not work and the wash will not start.

- Loading into a tray of detergents.

- Selection of the required washing program. Depending on the type of control, manual or automatic, such a choice is made either using the rotary mechanism, or by pressing the button for the corresponding washing mode.

- Control of the beginning of the flow of water into the drum and the start of its rotation.

- Control over the activation of the heating element during the washing process - by simply touching the glass part of the door.

- After the end of the wash cycle, open the ram and remove the washed items. Removal of debris, hair and other particles from the rubber cuff that did not come out through the drain channels.

It is also recommended to leave the drum ajar for a few minutes after the end of washing to ensure that it is dry.

How to care for your washing machine

The main methods of care include periodic cleaning of the insides with a special solution that prevents the formation of scale. It is possible to add such products with each wash, which will provide the machine with a long service life.

Periodically, it is recommended to check the debris collection compartment at the bottom of the machine to ensure that no particles accumulate inside.

Understanding the principle of operation of the automatic washing machine, you can provide yourself with reliable equipment for a long time to return your clothes to their former shine.

Video: the principle of the washing machine