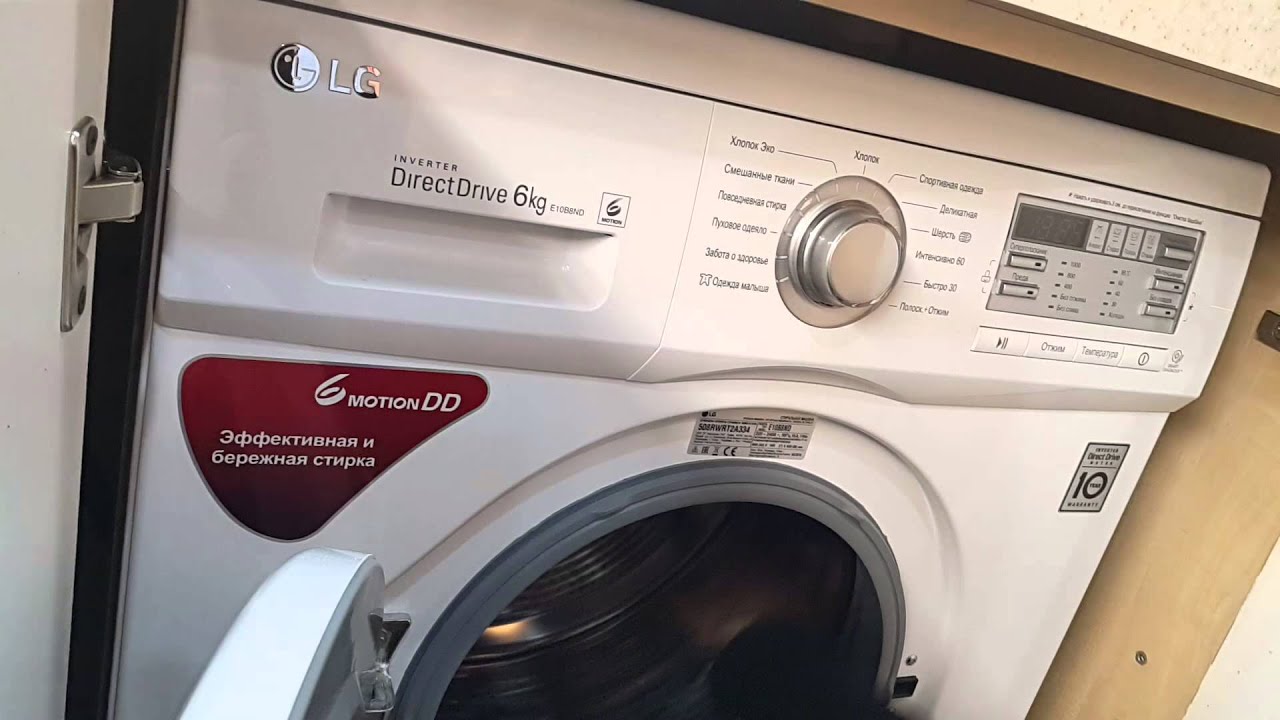

LG Direct Drive Washing Machine

LG pioneered direct drive washing machines. The first models were released at the beginning of the 2000s. What are the advantages of such machines? And do they have any disadvantages?

Direct drive principle

A drive is a system for transferring energy from a power source to an actuator. In direct drive machines, the motor is attached directly to the tank. In this case, there are no parts that rub against each other (for example, brushes).

The Direct drive is constructed from a permanent magnet and 36 equally spaced AC coils. From the control unit, signals are alternately transmitted to each coil, and they rotate around the core. All elements are located in one housing, which can be disassembled if necessary.

Advantages

The main advantage is the low noise level. Models that do not have a direct drive are equipped with a belt and pulley, which create noise during the operation of the unit.

Direct drive is always a good balancing of the machine, which means there are no strong vibrations. The engine breaks down less often, the life of the washing machine increases.

The quality of washing and spinning is much higher than that of machines with a belt. This is due to the large number of revolutions. Direct-drive washing machines are more energy efficient.

Frequent breakdowns

Of course, with the advent of new technologies, the lifespan of machines has become much longer. However, since the changes did not affect all the units of the unit, the machine is not insured against breakdown. In addition, the disadvantages include the high cost of direct-drive washing machines and expensive repairs in the event of a breakdown.

An important caveat: LG provides a warranty for machines with direct drive up to 10 years. Agree, this figure says a lot. And yet there are the most vulnerable spots.

Drain pump

Most often, breakdowns of the drain pump are caused by design features, but sometimes they also arise due to irrational operation. Important: make sure that the drain hose is connected and positioned correctly, clean the filters regularly and do not allow small debris to enter the drum of the machine.

Heating element

Tubular electric heater (TEN) is another weak link in the unit. Most often, he "suffers" due to power surges and poor quality water. To protect yourself, it is recommended to use special anti-scale products, as well as water filters. Don't forget to install a voltage regulator.

Although all these operations will require certain costs, believe me, as a result they will cost you less than replacing the heating element. In fairness, it should be noted that replacing the heating element is considered one of the simplest operations for repairing washing machines, and often even amateur craftsmen can easily cope with it.

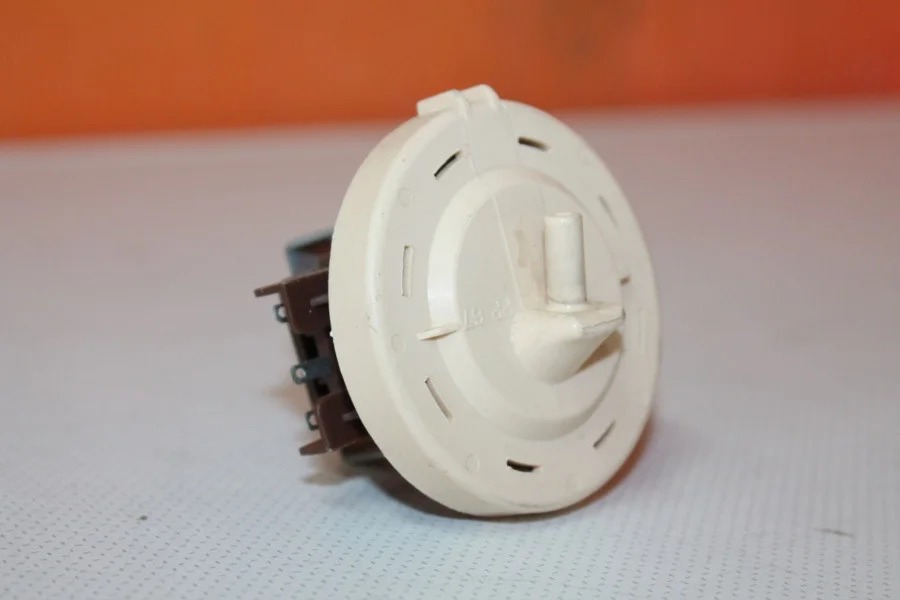

Pressostat

The task of this device is to control the water level in the tank. Most often, a malfunction of the pressure switch is indicated by poorly wrung out linen, self-draining of water, or a complete lack of water when the process is running. This failure is confirmed by the corresponding error codes, which are displayed on the electronic board.

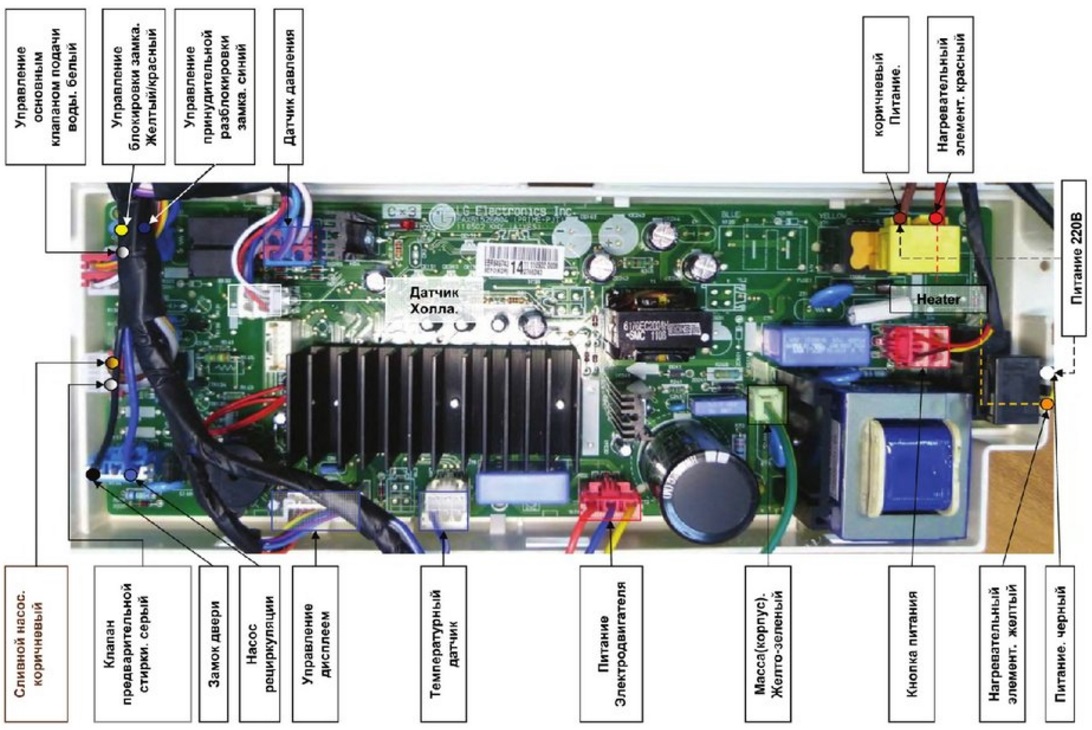

Defective electronics

This problem is the rarest, but in order to fix it you will have to contact a specialist, and such repairs will not be cheap. But it is very simple to identify this particular malfunction: the machine does not turn on, gives out a certain error code, does not switch stages during operation. You can protect yourself from such problems if you follow the operating rules, use a special voltage stabilizer and avoid water ingress on electronic circuits.

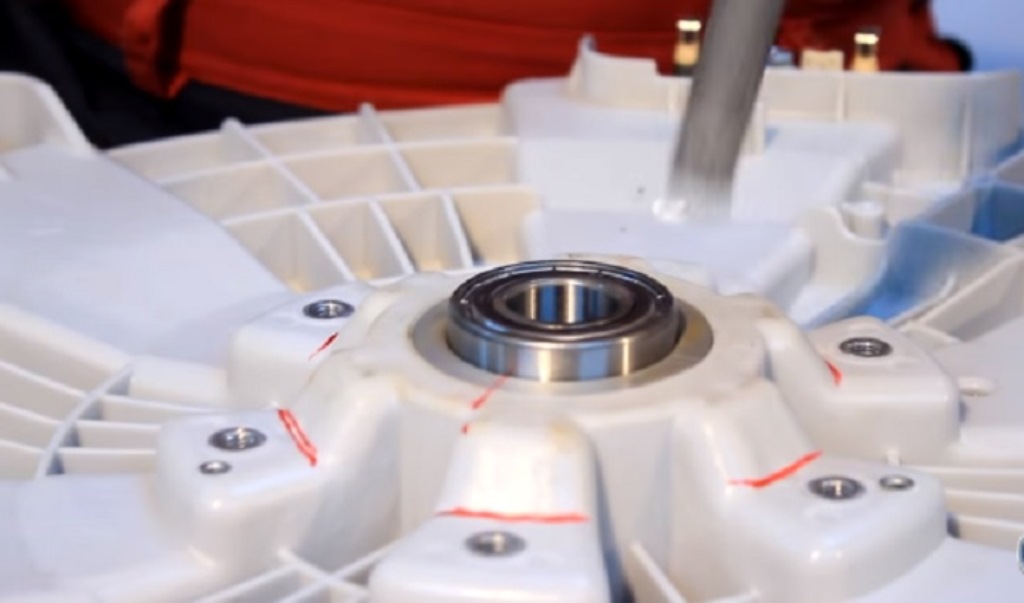

Bearings

Bearings in direct drive washing machines are a weak point, they wear out quickly enough. Due to the design features, it is the motor that is experiencing the most serious stress. The unnatural creak or knock of the drum during intensive rotation (during spinning) will eloquently "tell" about breakdowns.

To make sure that something is really wrong with the bearings, it is recommended to free the drum from the laundry and turn it by hand. If in the process you notice a backlash or creaking, then the bearing needs to be changed. By the way, LG specialized stores always stock spare bearings for direct drive machines.

Other malfunctions

Also among the common malfunctions is the failure of terminals and wires, which, in turn, can lead to a breakdown of the control module. There is also a risk of engine failure. Since it is located in close proximity to the drum, in case of depressurization and leakage, it will suffer first. This breakdown happens extremely rarely, but it still takes place. In this case, repairs are very expensive, and besides, this malfunction is not included in the warranty repair.

Preventive measures

With household appliances, as well as with health: prevention is cheaper than treatment or repair.

And after all, the recommendations are extremely simple:

- Plug the washing machine into a separate outlet;

- Do not use surge protectors;

- If your water supply system has increased hardness, be sure to install a filter. Thus, you will prevent damage to the heating element;

- Use descaler;

- Many models have a drum cleaning function. Run it every 15-20 washes;

- Before placing items in the drum, inspect them carefully so that no small objects fall into the drain system and damage the drum.

Although LG's direct drive washing machines are not perfect today, they make life a lot easier. Well, breakdowns can also occur due to a factory defect, and not just due to improper operation.Remember: observing preventive measures for the use of household appliances, you can extend its service life.

Video: LG Direct Drive Washing Machine Review