Why do we need pads for the legs of chairs and how to make the lining yourself

The legs of chairs and stools often scratch the floor covering, leaving marks on it. All this leads to premature wear of the finish, and there is a need for repairs. The installation of special pads on the legs, which can be made by hand, will help to avoid this. The procedure is quite simple, does not require the use of special knowledge and efforts.

Overlays - why are they needed

Any stands for furniture legs can improve the performance of chairs and armchairs.

They perform the following functions:

- protection of the floor covering from damage, scratches, premature wear;

- noise reduction - overlays drown out the sounds that occur when the chair is moved (a bar cabinet can make a lot of noise when moving on a tile);

- assistance in moving - difficulties can often arise when carrying heavy chairs around the room, soft pads allow you to easily move furniture across the floor, no traces will remain;

- increased stability - stickers on the legs of the chairs prevent the chairs from sliding over the surface, which increases the safety of operation (all ladders have rubber pads);

- aesthetic function - onlays can be used as a decorative element.

Varieties of stickers and overlays

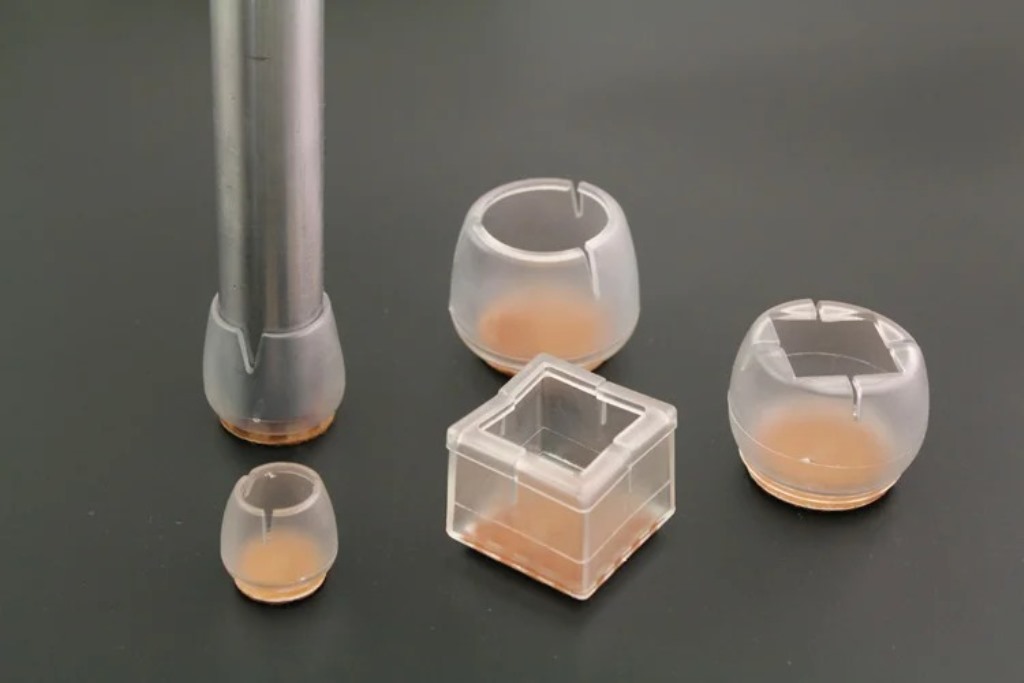

When choosing overlays, the type of legs must be taken into account. The legs are stationary, adjustable and wheeled. The first option is considered the most common. In this case, caps are installed on the legs or special nozzles are glued. Pads are also glued to the adjustable legs from below. The second option involves the manufacture of plastic nozzles with an adjustable screw.

Advice. Wheel feet stickers are not provided. The only way out of the situation is to replace the wheels with more elastic ones. They are sold in hardware stores.

How to make a sticker on a chair leg with your own hands

If you need to make protectors for the legs of chairs with your own hands, it is recommended to compare several options. There are many ways to make protectors. They can be cut from large pieces of fabric, rubber, felt, glued with hot glue and a hair dryer. Sometimes it is easier to buy special pads from the store and stick them on. The procedure is quite simple, does not require the use of special knowledge and skills.

Required materials and tools

You should think about the need to make overlays for chairs at any stage. It's never too late to make your seat safer and more comfortable. Some pads make it easier to move furniture across the floor, while protecting the floor from damage.

The following materials are used in the manufacture of protectors:

- silicone;

- felt;

- rubber;

- plastic;

- polyurethane;

- the cloth;

- leather.

When choosing materials for the manufacture of pads for furniture legs, their properties should be taken into account. Sliding materials are not recommended for the manufacture of overlays for tiled floors. In this case, the use of felt and Teflon should also be abandoned. Felt and Teflon protectors come in handy when you need to move heavy furniture over the surface. Soft plastic silicone and rubber are suitable for wooden chairs. Cork - the option is suitable for stationary furniture, it is not recommended to use it for chairs.

All fabric materials absorb dust and dirt, and various debris sticks to them. Getting rid of dirt is often difficult. The felt quickly wears out and becomes thinner; rather quickly, it may become necessary to change the lining.

Important! Linings made of different materials often perform different functions, so the choice should be taken as responsibly as possible.

Plastic is considered a universal option; it is suitable for different floor coverings. For the manufacture of overlays, you will need "Polymorphus" plastic (thermoplastic balls), any container, a tool for application. The melting point of thermoplastic is 65 degrees. The material becomes viscous, like plasticine, and can be used to create different shapes.

The cooled thermoplastic hardens, the material, if necessary, can be painted in any color. Ready-made pads easily stick to different surfaces, there is no need to use adhesives. There is no need for tools in the manufacture of protectors. The technology is available to everyone.

Preparation

It is not recommended to use boiling water to soften thermoplastic, this will avoid burns. The water must be hot enough for the thermoplastic to become plastic. The lightening of the material indicates that you can start sculpting. The balls should be kneaded until the desired shape is obtained.

When heating thermoplastic, it is allowed to use a construction hair dryer, a soldering station. In the latter case, it is possible to adjust the temperature, contact with water is excluded. An alternative option is to warm up the thermoplastic in a water bath.

During the heating phase, it is recommended to add powder paint of the required shade, which will help to obtain the desired color. It is recommended to add the paint with uniform stirring, knead until smooth.

To increase the grip, it is also recommended to prepare the surface of the legs in advance. It is recommended to use fine sanding paper for processing.

Step-by-step manufacturing instructions

Stages of overlay production:

- prepare softened thermoplastic;

- apply the composition to the prepared surface in the form of lids - they will close the ends and grab the lower part of the leg;

- let the plastic harden.

Placing the product in cold water will help speed up the curing process. Reliability of fixation is ensured by shrinkage.

Important! When making attachments, you should adhere to a single style.

Tips and nuances

When making protectors for chairs, you should choose the simplest, most affordable and practical option. The pads provide protection for the floor covering from damage, scratches. Thermoplastics are sold in art stores where you can also buy paint. All defects are easily corrected, the material should be melted again and used for other purposes.

Thermoplastic is considered ideal for making chair leg protectors. Its advantages are considered to be hardness, ease of use, affordability, durability. This is ideal for making do-it-yourself protectors.

In this case, there is no need to use glue, after which traces may remain on the surfaces. Thermoplastic pads last longer than fabric pads. The material is resistant to dust and dirt, does not need special care.

Video: anti-scratch chair leg pads